What do we do?

Design, build and deliver modular skid mounted plants, ready to run for pilot or production scale around a variety of equipment. Integration of structurals, process and utility piping, pumps and field instrumentation along with automation and control panels, which can be erected at site within a week of delivery.

“Modular systems help you get your process technology to the market faster, safely and on budget.”

How does that help you?

Working with a single company avoids cluttered project teams, and allows you to execute your project with simplified communication and clear accountabilities. We construct our skids in controlled conditions inside our shop, so the quality of the skids is superior to what is achieved on field in open conditions. Fast erection and reduced site work ensure that there is minimum plant shutdown time.

“From design to fabrication, your project will be executed from start to finish with a single point of contact from Integra’s team.”

Why should you choose us?

Our team has more than 10 years of experience in design, engineering, fabrication and transport of modular skid mounted plants, for customers in India and abroad. Detailed 3D modelling of the plant including the smallest of components will help you visualize the entire operations, and take safety reviews at the right stage. Extensive Factory Acceptance Testing will ensure you have minimal troubles at site.

“Integra’s experience in engineering, project execution, fabrication and factory testing will bring to you enhanced value and productivity on a fixed-price lump-sum basis.”

Compressing Timelines

Delays and cost overruns can seriously impact your commercial success in competitive markets.

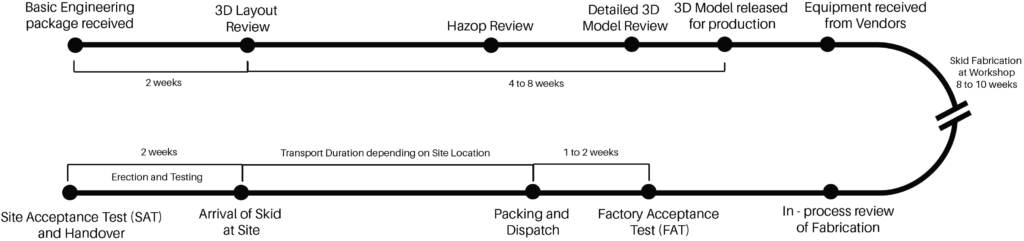

With Integra, you can take a lead in market time by compressing the project’s completion time, as site permits, civil work and site modifications can take place parallelly with the fabrication of the plant at our facilities. Our strong project management experience will help you keep your project on track.

Frequently Asked Questions

Can all types of equipment be modularized?

Generally, yes. Integra engineers will evaluate the General Arrangement drawings of the equipment and assess if the plant can be converted into a modular system at the proposal stage itself.

How are modular plants transported?

The plant is divided into several modules, the contents of which can be transported without dismantling. These modules are designed for transport over road or sea. They are packaged in a protective wrapping and inserted into containers, or over flat bed trailers. All the necessary handling instructions for each module are provided on the packaging. Integra’s engineers also provide on-site installation support following delivery to the site.

Are modular plants necessarily compact?

Modular Skids can be as compact as we design them to be. Depending on the available space at the client site, the plants can be optimized to fit into a compact space or alternatively, can be designed to include plenty of free space within for complicated handling or future expansion.

What is Client’s scope in case of modular supply?

The Client needs to provide Integra with the Basic Engineering Package, and has to select and place the order for equipments in the plant with a Vendor. Once the GA drawings of the equipment are received, the civil load of the plant will be calculated by Integra. The Client has to be ready with the foundation of the plant at site before the modular plants are delivered by Integra. The details of the scope of supply will be clearly spelled out in our Proposal document, so there are no surprises during execution.