Engineering

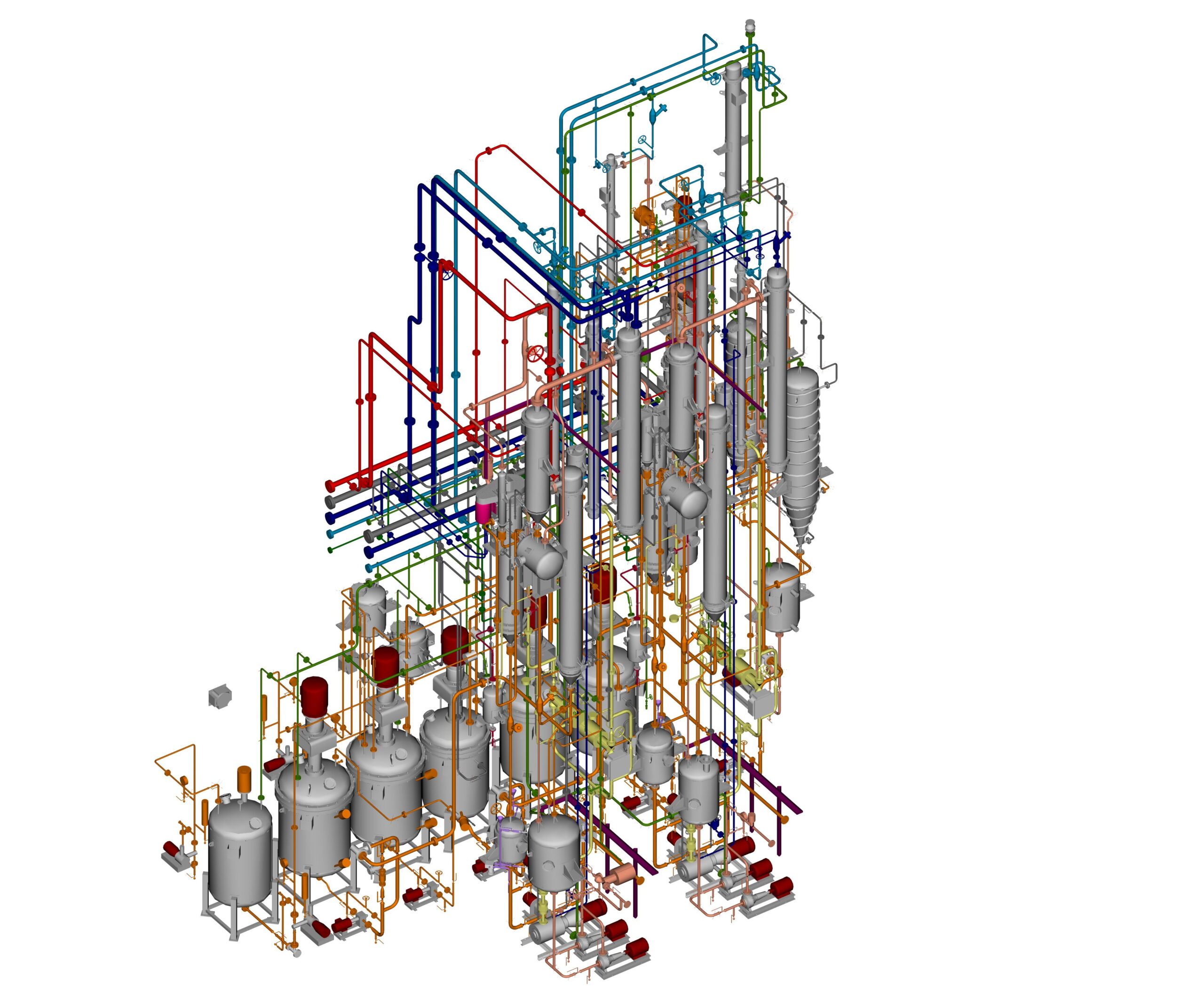

Once the Basic (front – end) Engineering package is received from the client, the Integra team will study the documents and first transform it into a modular skid form. After detailed discussions and approval from the client in this step, the Piping Engineering team of Integra will work on a database linked plant design software to create a highly detailed 3D model of the plant. At the same time, the Instrumentation team will work on the PLC programming to ensure a efficient and effective HAZOP and operational study of the plant with the Clients team.

In parallel, the structure of the plant will be designed by the Mechanical team of Integra to ensure that the modular plant is designed and built for safe lifting / handling during dispatch and erection and can survive the transport conditions in the assembled form.

Our designs are tailored to the specific needs and requirements of our each unique customer. We can meet your required standards and preferences, including preferred suppliers, providing a plant with components that are familiar to your operators and maintenance staff.

“Thus our skid mounted plants are created with integrated collaborative know how from our designers, workmen and project engineers to maximize efficiency and cut risks and costs.”

Skid Fabrication

At Integra, both the detailed engineering and fabrication of the systems takes place at the same location, providing a high degree of efficiency, quality and control on timelines. Integra has a manufacturing facility equipped with heavy overhead cranes and experienced workmen that can build skids to various Code standards.

Each segment of process and utility piping is hydrotested 100% before installation in the skid. Pumps, Instruments, and other accessories are each tested as per test protocols in -house before installation into the skid. The instrumentation and its communication wiring up to the Junction Boxes and with the Control Panel is loop tested to ensure error free configuration.

At the Factory Acceptance Test (FAT) stage, the entire plant is assembled for the client to physically walk through, and comprehensively inspect with the concerned teams first hand.

“Our in-house extensive factory testing speeds up site commissioning and start-up”

Modular Supply

Integra has a know how of building skids into a modular form, which can be dismantled in blocks, with the internal equipment, piping and instrumentation remaining intact.

This ensures that the assembly of all the components is done inside the Integra workshop, under the close supervision of our experienced project engineers, and tested for smooth integration before dispatch to the site in the form of several assembled modules instead of loose components. Errors and rework are minimized, ensuring you’re delivered a high-quality plant that exceeds your requirements.